The Structure and Operating Principle of the Roller

Release time:

2021-11-12

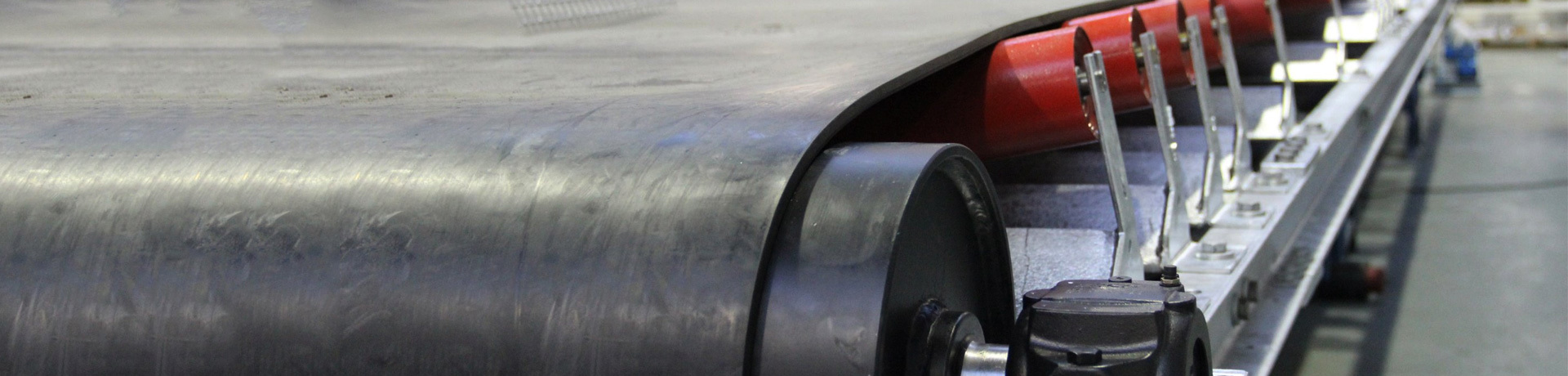

The drum is primarily composed of a bearing housing, bearings, and baffles. Its working principle is based on frictional rotation—specifically, using rolling friction instead of sliding friction to minimize energy loss—and power transmission is achieved through the movement of a drive belt.

The drum is primarily composed of a bearing housing, bearings, and baffles. Its working principle is based on frictional rotation—specifically, using rolling friction instead of sliding friction to minimize energy loss—and power transmission is achieved through the movement of a drive belt.

Keyword:

Next article

Related News

In the mining sector: Challenges include dealing with ore dust, high humidity, and impact loads. The corrosion resistance and wear durability of polymer rollers can reduce equipment replacement frequency and lower maintenance costs.

2025-10-20

Performance characteristics of idlers

Drag reduction and efficiency enhancement: Rollers generate more than 70% of the total resistance in conveyors. High-quality rollers can lower the coefficient of friction, thereby reducing energy consumption. For instance, polymer rollers boast a low coefficient of friction, significantly boosting conveying efficiency.

2025-10-20

The Structure and Operating Principle of the Roller

The drum is primarily composed of a bearing housing, bearings, and baffles. Its working principle is based on frictional rotation—specifically, using rolling friction instead of sliding friction to minimize energy loss—and power transmission is achieved through the movement of a drive belt.

2021-11-12

The functional features and applications of rollers

High transmission efficiency: The large friction between the roller and the conveyor belt or other materials ensures high transmission efficiency, minimizing energy loss.

2025-10-20

Classification and Functions of Idlers

Buffer idlers: Installed beneath the material-receiving section, these components absorb material impact via structures such as spring plates and rubber rings, helping to extend belt life. They are ideal for applications with frequent material discharge, such as power plants and cement factories.

2025-10-20

Whatsapp:

E-mail:

Message

Whether it's about products, services or general inquiries, we're here to listen and answer your questions.