Application fields of conveying equipment

Release time:

2025-05-06

Logistics and express delivery industry: Using belt conveyors, roller conveyors, chain conveyors, mesh belt conveyors, continuous elevators, screw elevators and other conveying equipment to improve conveying efficiency and reduce damage to conveyed goods.

Conveying equipment is widely used in modern industrial enterprises, such as fine chemical engineering, pesticide mining, building materials, and food industries. Specifically, it is also applied in the following scenarios:

Logistics and express delivery industry: Using belt conveyors, roller conveyors, chain conveyors, mesh belt conveyors, continuous elevators, and screw elevators to improve conveying efficiency and reduce damage to conveyed goods.

Food processing industry: Using various forms of food production conveyors, such as straight lines, turns, inclines, lifts, and telescopic types, to meet different process requirements.

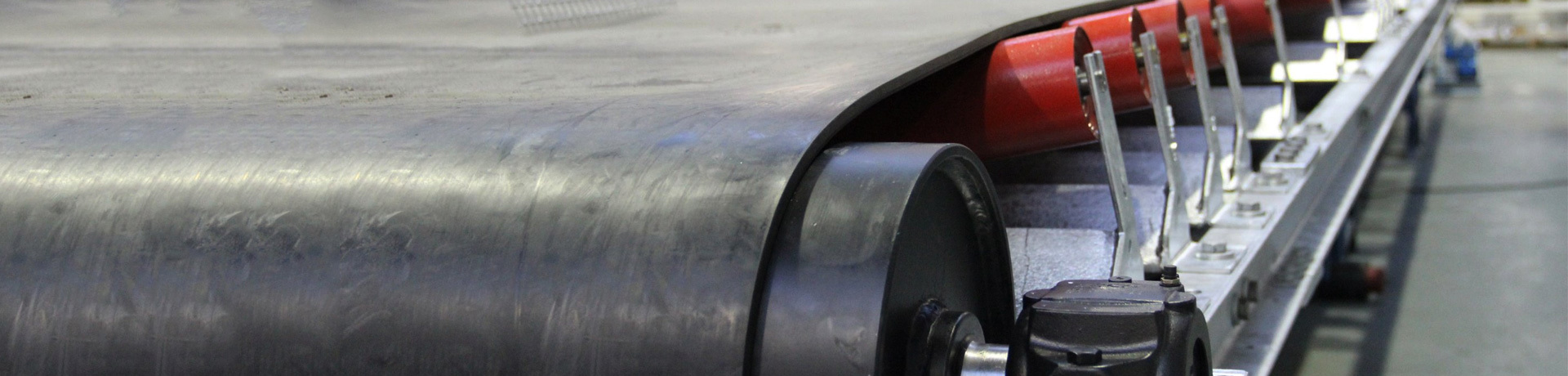

Tire industry: Using a complete conveyor system composed of conveyor rollers and conveyor chains, including various functional conveyors and belt conveyors.

Daily chemical industry: Using flexible chain conveyors, flat chain conveyors, and roller conveyors to meet the production and transportation needs of cosmetics and other products.

Keyword:

Next article

Related News

Advantages of slat conveyor belts

For decades, industrial conveyor systems have played a vital role in manufacturing, revolutionizing the way materials are transported in factories and warehouses. From simple roller conveyors to complex automated systems, the evolution of these systems has been remarkable. This article will delve into the history and advancements of industrial conveyor systems, tracing their journey from basic manual systems to sophisticated, high-tech solutions.

2022-07-28

Development of industrial conveyor belts

For decades, industrial conveyor systems have played a vital role in manufacturing, revolutionizing the way materials are transported in factories and warehouses. From simple roller conveyors to complex automated systems, the evolution of these systems has been remarkable. This article will delve into the history and advancements of industrial conveyor systems, tracing their journey from basic manual systems to sophisticated, high-tech solutions.

2022-01-10

The structure and working principle of a drum

The roller mainly consists of a bearing seat, bearings, and baffles. Its working principle is based on frictional rotation, that is, using rolling friction instead of sliding friction to reduce energy loss, and power transmission is achieved through the movement of the drive belt.

2021-11-12

What are the maintenance methods for flame-retardant conveyor belts?

Regularly conduct visual inspections of the entire length of the conveyor belt. Check for signs of wear, such as thinning, cracks, cuts, or abrasion of the conveyor belt surface. Pay particular attention to areas where the conveyor belt contacts rollers, pulleys, and loading/unloading points. Also check for any signs of damage to the fire-resistant layer, such as peeling or delamination.

2025-05-06

Operating temperature range of industrial conveyor belts made from different materials

Industrial conveyor belts are mechanical devices widely used in various industrial fields. Their function is to transport materials from one location to another. Appropriate conveyor belt materials must be selected for different industrial scenarios and material types to ensure a longer service life. Different materials have different operating temperature ranges, which will be introduced below.

2025-05-06

Whatsapp:

E-mail:

Message

Whether it's about products, services or general inquiries, we're here to listen and answer your questions.